Meibao sodium silicate production plant company for detergent industry1

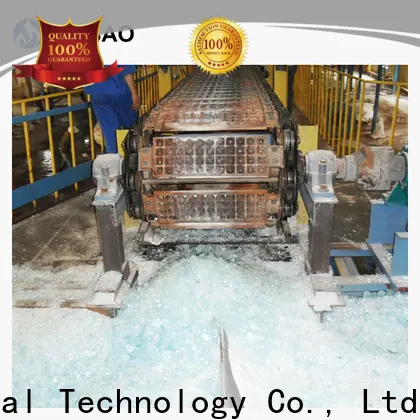

sodium silicate production plant

description

The product produces little heat during operation. During the production process, it will be equipped with a substrate with heat dissipation performance, playing a role of cooling. The product is widely applied to cosmetic, food, biological and pharmaceutical industries

sodium silicate production plant

SPECIFICATIONS

The unique formula is provided for free with the product. The product has been sold to many well-known brands, including Unilever, US P&G, Germany Henkel, NICE Group, etc. The product has a high-speed disperser to make the materials mix evenly.

Suggested Videos

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

no data

Product

Quick Link

Contact Us

Tel: +86 0571 86036281

Email: mbl@cnmbl.com

Whatsapp: +86 13818105145

Fax: +86 0571-85184885

Office address: Floor 14th, ZMI Plaza, No.445, Kaixuan Rd, Hangzhou, China

Factory address: No.150 Xinan Town, Deqing Hangzhou, Zhejiang, China