Meibao rockwool sandwich panel production line manufacturer for rock wool3

MOQ:

1 set

Payment:

L/C, D/A, D/P, T/T

Place of Origin:

China

Brand:

Meibao

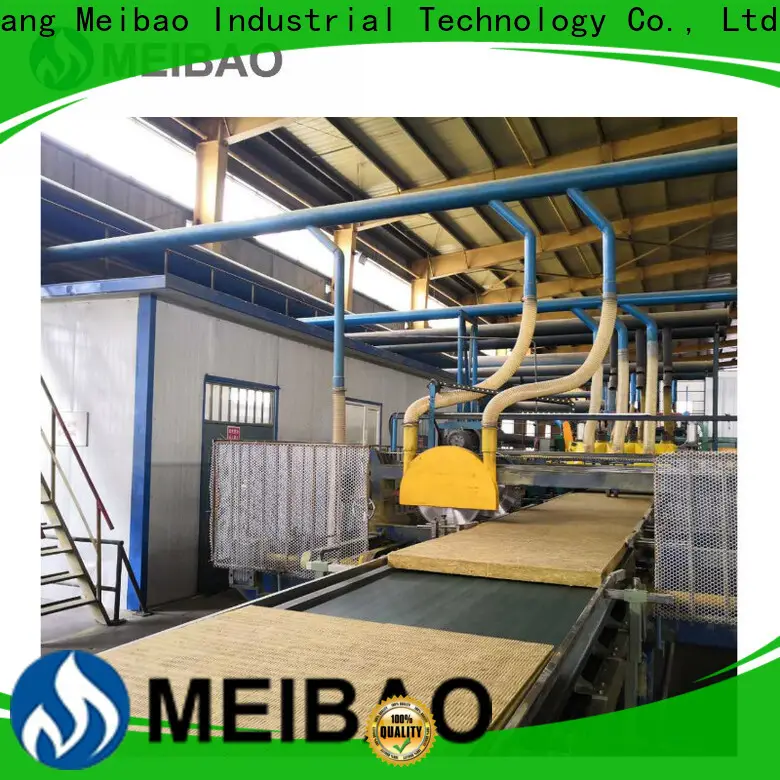

Rock wool production line

Our company can provide complete sets of rock wool production line, including process design, equipment selection, non-standard equipment manufacturing, installation and commissioning and operation training.

The process design fully considers production safety, product quality, operating costs, environmental emissions and investment. Effectively recycle and use the cupola exhaust gas and incinerate the curing furnace tail gas. We follow the 'energy saving, emission reduction standards.' We have successfully provided equipment and technical services to dozens of rock wool production companies.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

no data

Product

Quick Link

Contact Us

Tel: +86 0571 86036281

Email: mbl@cnmbl.com

Whatsapp: +86 13818105145

Fax: +86 0571-85184885

Office address: Floor 14th, ZMI Plaza, No.445, Kaixuan Rd, Hangzhou, China

Factory address: No.150 Xinan Town, Deqing Hangzhou, Zhejiang, China