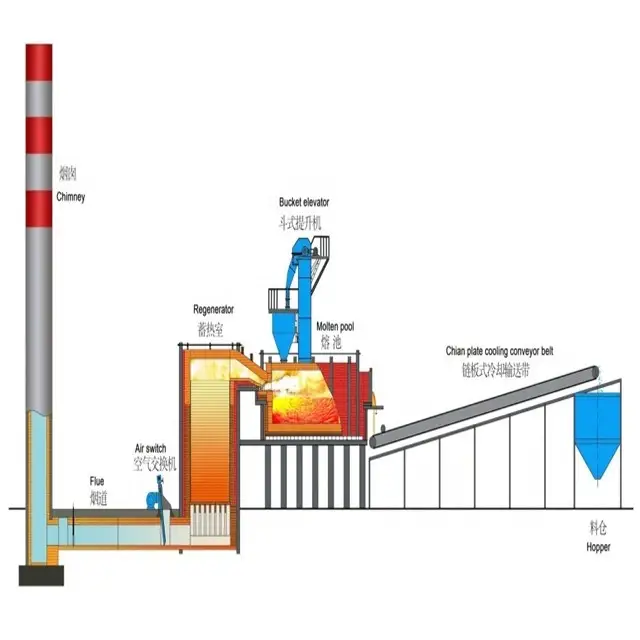

The main raw materials of the solid sodium silicate production are soda ash and quartz sand. The process is batching, firing and forming. The main equipment is feeding system, slurry preparation system, furnace (molten pool, Regenerative chamber, flue, chimney), combustion system, forming chain plate machine and control system. Our company can provide the process designing, equipment manufacturing, installation, debugging and training for the solid sodium silicate production line with a daily output of 10~160 tons and a modulus of 2.0~3.5 according to the customer requirements.

Regenerative chamber type water glass furnace/ Sodium silicate plant equipment

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Product Description

Regenerative Chamber Type Water Glass Furnace

Detailed Images

Certificate

Patents of the auromatic control system

Patents

Our customer

The ability to soften water of this product contributes a lot to various kinds of industrial equipment, which reduces the accumulation of dirt. The product ensures high operation efficiency and accuracy.

Apart from making people more attractive, this product enables them to project a certain personal image to others. The product ensures high operation efficiency and accuracy.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Related Products

no data

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs!

Frequently Asked Questions

Yes, if the customer needs a guarantee, we can offer.

We will communicate with our customers first, if they agree, we will be very happy to take you to visit our customers' factories and let you see the operation of the whole production line.

Yes, we welcome customers to come to our factory to communicate. The address of our factory: No.150 Xinan Town, Deqing, Zhejiang, China.

We have cooperated with Unilever, Indonesia P.T. Wings, Indonesia PT. Pacinesia Chemical Industry, Ittehad Chemicals Ltd(Pakistan), Singapore International Rubber Industry Co., LTD, US P&G, Germany Henkel, NICE Group, Guangzhou Liby Group and so on.

no data

Product

Quick Link

Contact Us

Tel: +86 0571 86036281

Email: mbl@cnmbl.com

Whatsapp: +86 13818105145

Fax: +86 0571-85184885

Office address: Floor 14th, ZMI Plaza, No.445, Kaixuan Rd, Hangzhou, China

Factory address: No.150 Xinan Town, Deqing Hangzhou, Zhejiang, China